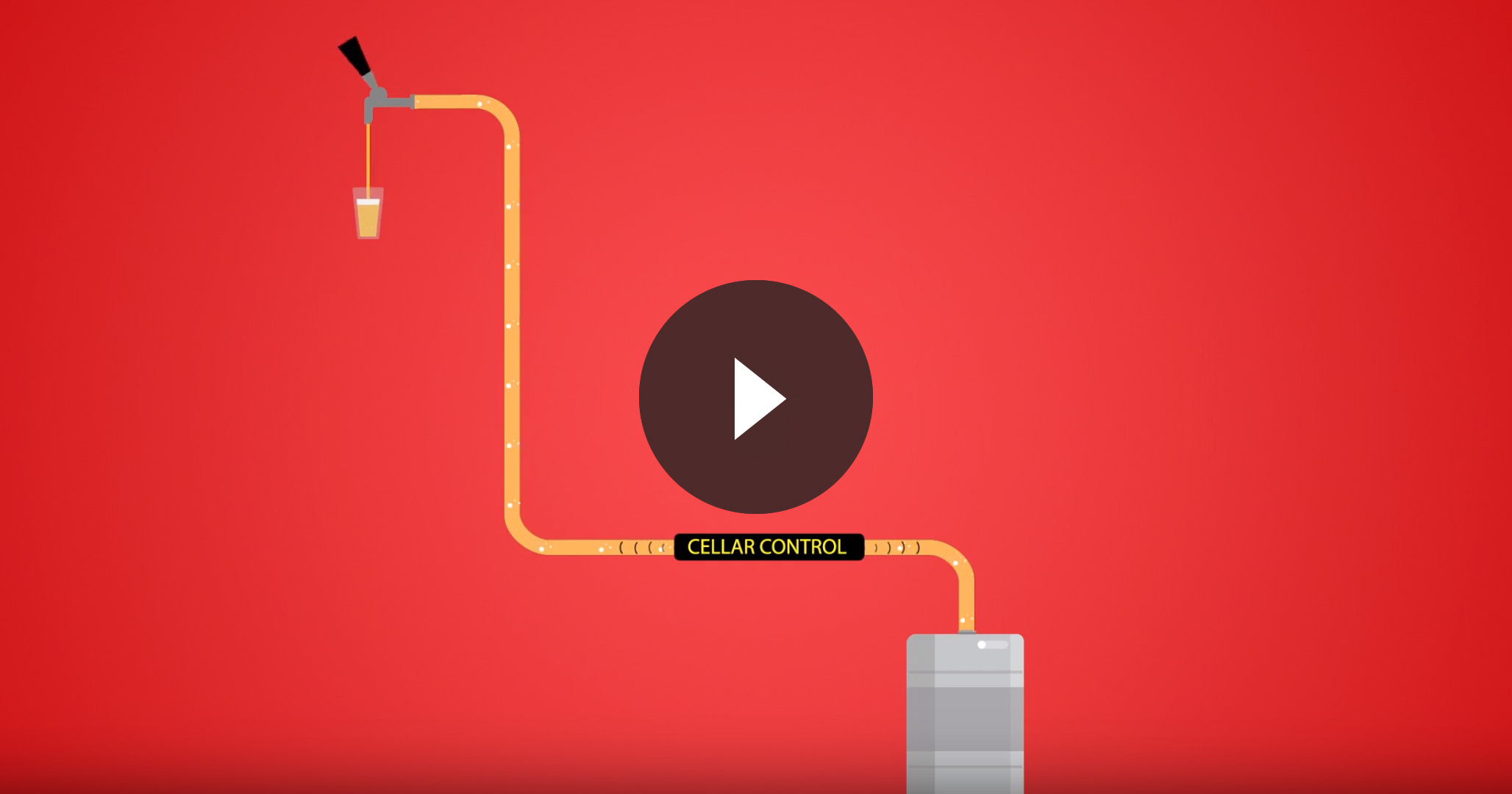

Consisting of a control unit and activators, CellarControl works 24/7 to protect your beer lines, improve beer quality and reduce wastage.

CellarControl is an addition to your current beer line system, that uses low frequency sweeping sound technology to inhibit biofilm growth. This technology is used in many industries worldwide, such as commercial pool treatment, town water treatment, hydroponics, medical, dental care and many more. The technology was first introduced into the Australian cellar industry in 2007 and has been used internationally since the early 1990’s.

Each CellarControl system features a control unit and activators (one activator for each main drop lead line, installed at the keg). The activators treat the beer lines 24 hours a day, 7 days a week, transmitting sweeping sound frequencies preventing build-up on the beer lines, meaning you only have to do a line clean every 6-8 weeks and you get a clean, great tasting beer – every time. The system is unobtrusive and uses little power.

With CellarControl, you only need to clean your beer lines 9 times a year, rather than 52 times a year. Imagine the savings in beer wastage, chemicals, labour and all other associated costs with your beer line cleans.

Easily retrofitted to any venue

CellarControl can be easily fitted to any existing venue, no matter the size, new or old. The system is install in the morning prior to service.

Perfect for all beers – especially craft beers

CellarControl works great with all beers and ciders. In fact, it’s regarded as the best craft beer cleaning system available.

Clean your lines the same way as before

Once installed, you clean your lines the same way as before – only less often. Use your current line cleaning chemical, or switch to Maxi-Enzyme for optimal results.

Extends equipment life

CellarControl has no negative impact on your current beer system – in fact, CellarControl has proven to extend the life of your cellar equipment.

How biofilm works – and why you need to prevent it.

Before CellarControl

Pictured – An illustration of biofilm growth within a beer line over time. The biofilm attaches and further spreads on the walls of the line, releasing harmful bacteria and increasing lactic acid counts, resulting in poor quality beer.

Biofilm is the cause behind the growth of bacteria within the beer line. Acting like a glue on the beer line walls and containing yeast and bacteria, it enables the further growth and spread of wild yeast, lactic acid and other harmful bacterias. Over time, this biofilm causes higher bacteria growth. Biofilm growth happens quickly, and within two weeks this can have a noticeable negative effect on your beer quality. Biofilm growth is typically treated by regular line cleaning.

After CellarControl

Pictured – Using scientifically proven sweeping sound technology, biofilm growth within the beer line is inhibited. With significantly reduced biofilm growth, spoilage bacteria is unable to grow and spread.

CellarControl technology inhibits biofilm growth within the beer line. Using scientifically endorsed sweeping sound technology, biofilm growth is drastically reduced, resulting in a cleaner tasting beer for longer – and enabling you to conduct beer line cleaning every 6-8 weeks, while still achieving optimal beer quality. Without biofilm growth, bacteria and lactic acid counts are kept at an absolute minimum, and ensuring your beer is served the way it was supposed to be – without the high cleaning costs.

Scientifically endorsed with extensive bacterial and scientific testing. Setting a new standard in draft beer quality.

CellarControl’s cleaning cycle has been tested and endorsed by EcoDiagnostics – a leading Government accredited laboratory specialising in beer testing for major brewers. Extensive testing across multiple venues has shown that CellarControl in fact improves beer quality compared to traditional line cleaning practices, while reducing line cleaning requirements. By using CellarControl, along with regular cleaning of tap and coupling equipment, you will have the best beer quality possible.

Dr Mark Castalanelli – EcoDiagnostics

Frequently Asked Questions

CellarControl recommends Maxi-Enzyme – the safest and most effective beer line cleaning solution available today. Powerful multi-enzymatic cleaner, HACCP Certified, near pH neutral and safe to use. Find out more at rightbeer.com.au.