Better quality beer with less cleaning.

Clean your beer lines every six to eight weeks – using powerful, scientifically proven preventative technology to reduce your beer line cleaning costs by up to 80%, while improving your beer quality. CellarControl is the new best practice in clean beer.

Download our guide to the perfect beer ?

CellarControl inhibits biofim growth within your beer lines, allowing you to serve the perfect beer – with less cleaning.

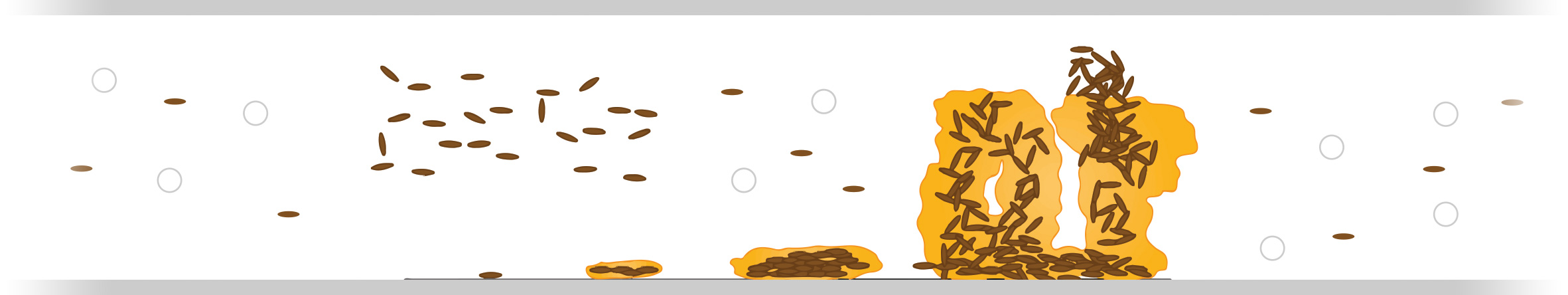

CellarControl treats the root cause of beer line contamination – biofilm. Acting as a ‘glue’ on the beer line walls and containing harmful yeast and bacteria growth, biofilm grows quickly, and is the cause of beer spoilage. CellarControl inhibits this biofilm growth, allowing you to serve great quality beer, with less line cleaning.

Better beer – for longer

Using scientifically-tested Sweeping Sound Technology, CellarControl drastically reduces biofilm growth, with improved beer quality compared to weekly/fortnightly cleans – so you can serve better quality beer, for longer.

Reduced wastage

CellarControl enables you to conduct beer line cleaning every 6-8 weeks – significantly reducing beer wastage, chemical and water usage, labour and time.

Scientifically tested

CellarControl’s cleaning cycle has been tested and endorsed by EcoDiagnostics – a leading Government accredited laboratory specialising in beer testing for major brewers.

We compared bacterial results (parts per million, or ppm) before and after CellarControl – with bacterial samples taken at 2 weeks following a line clean (before CellarControl) and 6 weeks following a line clean (with CellarControl). The lower the results, the better the beer quality – and CellarControl provides a significant reduction in harmful bacteria, with less cleaning. Here are the results for 150 Lashes at one of our venues.

“We offer a 6 weekly cleaning cycle using CellarControl, but still delivering the beer quality that customers expect. It’s without doubt all venues should be investing in this technology – I did!”

Clean your beer lines every six to eight weeks – reducing your wastage and line cleaning costs by up to 80%.

Save time and money with less wastage

CellarControl allows you to clean your beer lines every six to eight weeks, significantly reducing beer wastage, chemical usage and labour costs.

Improved OH&S and time management

With less handling of harmful chemicals and other equipment, you are improving your OH&S procedures – and you can spend more time serving and less time cleaning.

Works with all beer types

From your standard draught beers, to IPAs, stouts and all other craft beers – CellarControl works for every type of beer, and every brand, including ciders.

Reduced water consumption

By reducing your line cleaning cycle, you can save thousands of litres in water – a valuable environmental boost, especially in drought affected areas.

Trusted by industry leaders

CellarControl is used every day by Australia’s leading pub and club groups, and venues of all sizes – from small country pubs to major metropolitan clubs.

Low monthly rental

CellarControl is available on monthly rental, meaning the system is cash positive from day one – and allows us to offer the best customer service possible.

400+

Venues using CellarControl

With more venues of all sizes coming on board every week

$3m+

Per year saved

In reduced beer wastage and chemical usage

17,000L

Per week saved in beer wastage

Across all CellarControl venues

17 years

In operation

With venues using the system since 2007

Some of our clients from across Australia

“We recommend the system and feel it is a great addition to any beer system given the savings that can be achieved.”

“We did not advise our customers of the implementation of the CellarControl and have had no complaints, and commonly get compliments of having the best beer in town.”

“Beer wastage of 60 schooners per week has not only stopped but I am also able to sell those schooners previously tipped down the drain. I would recommend giving this system a go as what you save far exceeds the cost of the unit and there is no negative impact beer quality.”

“It is pleasing to note that our beer quality has not only been maintained, we received immediate feedback from our members that the beer tasted cleaner and was more refreshing to drink. I would highly recommend this system to anyone who would like to save staff time and serve a cleaner, fresher tasting beer.”

“We have 5 venues using the system, all of which have had considerable savings in beer, chemical, water and labour. I have no hesitation in recommending the CellarControl system to any venue.”

CellarControl recommends Maxi-Enzyme – the safest and most effective beer line cleaning solution available today. Powerful multi-enzymatic cleaner, HACCP Certified, near pH neutral and safe to use. Find out more at rightbeer.com.au.